Menu

Close

The roots of Fluidesign can be traced back to the endeavors of Diamond Aircraft Industries in London, Ontario, a region known for its thriving boatbuilding industry. This period marked a significant transition in the industry from traditional wooden boats to more advanced materials like carbon fiber. Diamond Aircraft, originally founded in Austria and recognized for its expertise in aviation, saw an opportunity to leverage its knowledge in aerodynamics and composite materials for the boating sector.

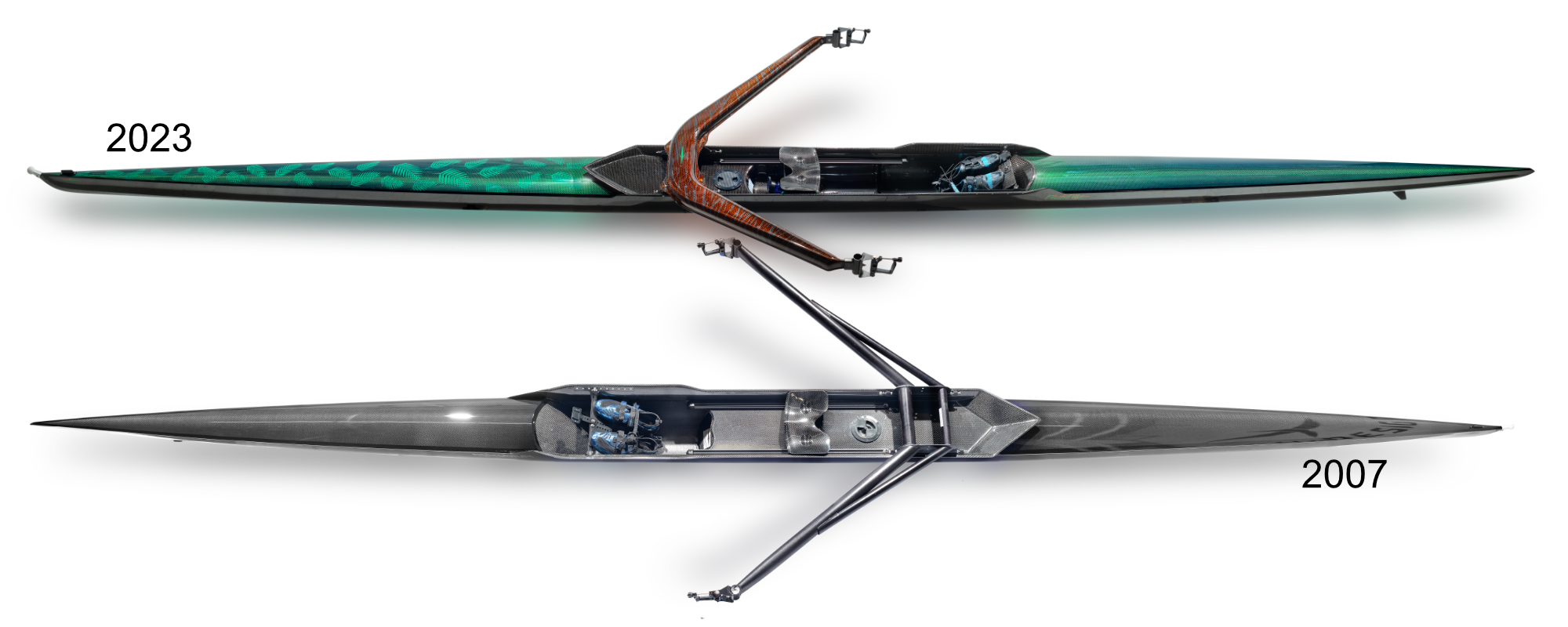

The initial concept for Fluidesign emerged from Diamond’s exploration into utilizing composite materials for various consumer products. The focus was on enhancing strength, durability, and flexibility while reducing weight—a crucial factor in competitive scenarios. The idea was that associating with an aircraft company could bring a competitive edge, especially for products where performance was key.

Diamond’s foray into the boating industry began with the development of a one-person racing shell, a venture that reflected a significant shift from the prevalent wooden construction to carbon fiber composites. The engineers at Diamond, leveraging their expertise in aerodynamics, embarked on a mission to transform this knowledge into effective hydrodynamic designs. The aim was to create a racing shell that minimized drag, a common enemy in both aviation and boating.

The innovation that set the Diamond boat apart was its wing-like outrigger, inspired by the company’s aviation background. This design was a departure from the traditional front-located outriggers made of welded tubular aluminum. The carbon fiber outrigger on the Diamond boat was strategically placed to create less drag, thereby enhancing performance.

Gord Henry, a consultant and researcher who had been hired by Diamond, played a pivotal role in the development of the racing shell. With his background as a rower for Canada in the 1998 Seoul Olympics and his experience as a manager of the Canadian National Rowing Team, Henry brought valuable insights to the project. His involvement was crucial in the phase where Diamond engineers concluded that the fastest hull shapes were not practical for rowing. This led to a shift in focus from hull shaping to material optimization to achieve the best possible speed with a rowable design.

The first prototype of the racing shell was a revelation. Henry’s experience rowing the prototype convinced him of its superiority. Despite Diamond’s decision to discontinue the project before the prototype went into full production, Henry recognized the potential of what they had developed. He decided to venture into business, producing and selling this new boat. Thus, Fluidesign was born, becoming a prominent entity in the London boatbuilding scene. Gord Henry later bought out his business partner and took over the management of the company.

In 2016, Fluidesign moved to its current location on Elias Street. The company prides itself on each hull being meticulously crafted by a team of skilled artisans, adhering to the highest standards of production. Fluidesign also collaborates with a network of specialized suppliers and partners, ensuring the quality and performance of their racing shells.

Fluidesign’s journey from a concept at Diamond Aircraft to a renowned manufacturer of racing rowing shells is a testament to innovation, expertise, and the pursuit of excellence in competitive rowing.

Fluidesign began as a project within , which experimented with various products before focusing on rowing shells. Gord Henry, an Olympian, was instrumental in the development of the company’s first racing shell. The company officially started in 1999, embracing carbon fiber composite construction and aerodynamic designs for improved performance.

Under Sam Roberts’ leadership, Fluidesign’s CEO and son of founder Gord Henry, the company continues its legacy in the competitive rowing industry. Sam’s deep connection to rowing, influenced by his father’s Olympic background, has been instrumental in steering the company’s innovative approach to boat manufacturing.

Gord Henry standing in a Fluidesign racing shell on stands at Lake Fanshawe (London On)

Each and every Fluidesign hull has been painstakingly built by a select group of artisans to the highest possible standards in our own production facilitiy. We also source specialist components from a network of dedicated suppliers and partners.